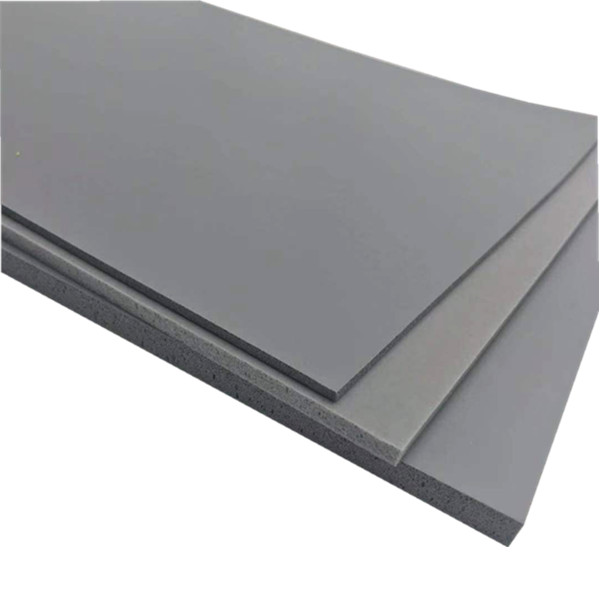

Product introduction

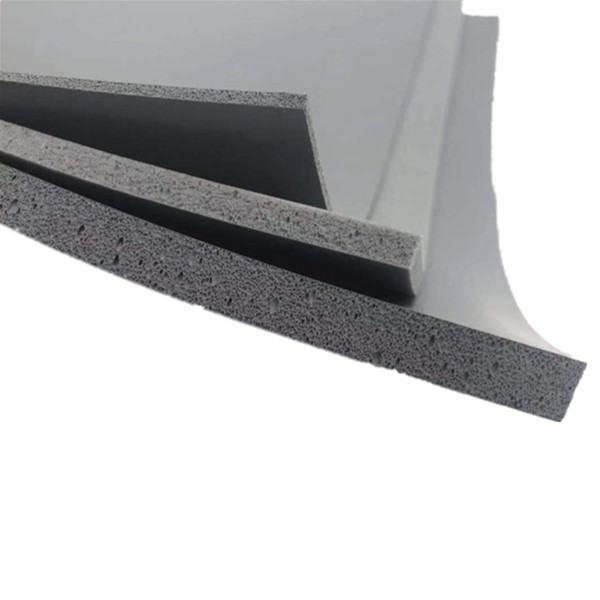

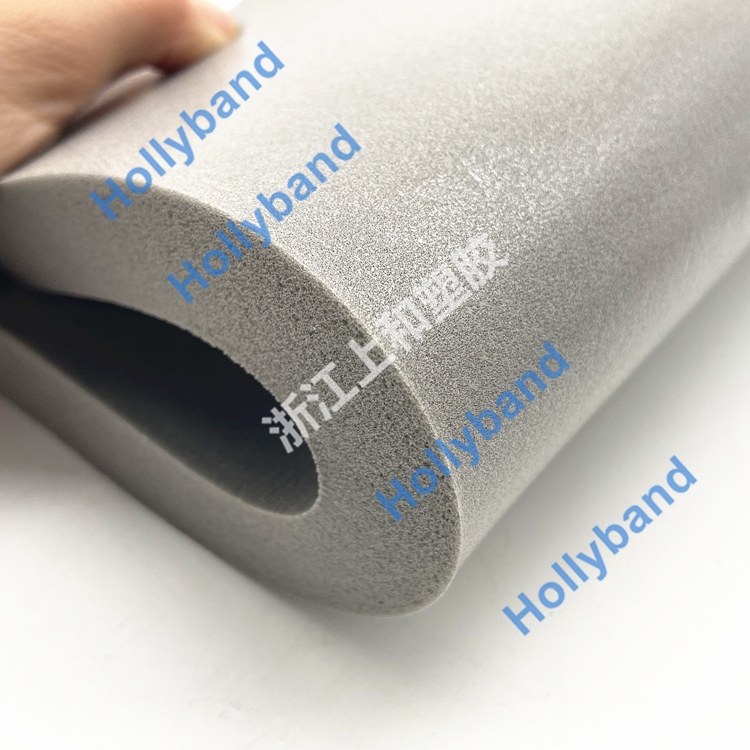

Silicone foam is introduced into foreign foaming technology, and the foaming is uniform. The density can be 0.4-0.6g/cm3 and the Shore hardness is 5-15A. Environmentally friendly, non-toxic, odorless, good resilience, good flexibility, no bubbles on the surface and no pores. Foamed silica foam has high strength, long service life, and high temperature resistance up to 250 °C. Foamed silica gel board is environmentally friendly, resistant to high and low temperatures, resistant to compression, acid and alkali resistant, and resistant to UV rays.

Product feature

1. The product has excellent heat-resistant air aging performance, ozone resistance, insulation, and is resistant to fuel oil and lubricating oil.

It can work in air or oil medium under the temperature of -60~+250 °C.

2. Strong sealing ability, can effectively prevent tiny particles and rain.

3. Sealed, dustproof, moisture proof, airtight and shading, vibration isolation, fire prevention

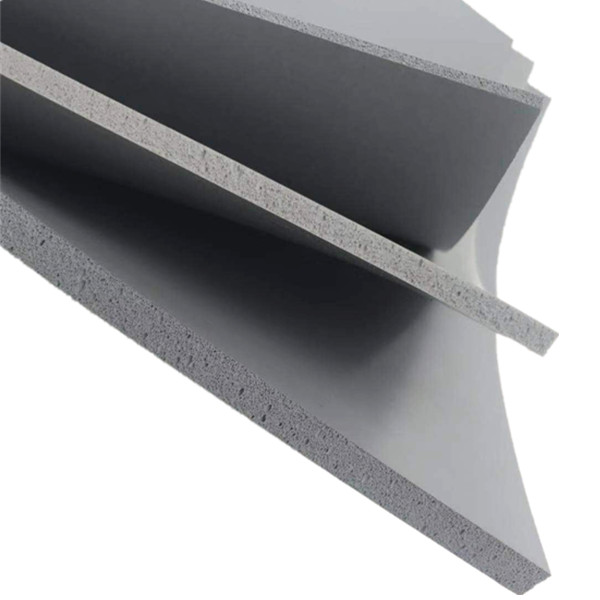

4. Use vibration isolation inside electronic equipment and vehicles

5. It can be used to punch all kinds of sealing gaskets and pads with strict requirements.

6. When the water is exposed to moisture or the temperature rises, the change is small. Even if the silicon dioxide generated by the

short-circuit combustion is still an insulator, this ensures that the electrical equipment continues to work, so it is most suitable to make wires,

cables and lead wires.

Product application

1.Printing equipment

2. Electronic appliances

3. Mechanical seal

4. Insulation

5. Decorative materials

6. Cabinet

7. Bathroom

8. Floor

9. Building template

| Specification Sheet for:Silicone foam | |||||

| Material Properties | Unit | Test Method | Physical standard value | ||

| Colour | -- | Black,grey.red | |||

| Thickness | mm | -- | <500mm | ||

| Width | mm | -- | 350 | ||

| Density | kg/m3 | ASTM D 1056 TEST D | <1(70℃test) | ||

| Compression deformation | % | <5(100℃test) | |||

| Tensile Strength | Kpa | ASTM D 412 | 450 | ||

| Tensile elongation | % | ASTM D 412 | 95 | ||

| Flame retardancy | UL94 | V-0 and HF-1 | |||

| Flame diffusion index | Ls | ASTM D 162 | <25 | ||

| Smoke density | Ds | ASTM E 662 | <20(15mintest) | ||

| <50(4mintest) | |||||

| Toxic gas emission rating | -- | SMC-SOO | Pass | ||

| Water absorption rate | -- | Internal Test 24Hrs | 3.80% | ||

| Dielectric constant | -- | ASTM D 150 | 1.37 | ||

| Dielectric strength | KV mm | ASTM D 149 | 3.96 | ||

| -- | ASTM D 495 | 92 | |||

| Physical resistivity | ohm cm | ASTM D 257 | 10 | ||

| Thermal conductivity | -- | ASTM D 518 | 0.09 | ||

| -55 Celsius low temperature distortion | -- | ASTM D 1056 | Pass | ||

| Recommended temperature | SAE J 2236 | -55~200 | |||

| Recommended intermittent use temperature | ℃ | Internal | 250 | ||